This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Game Changing Gripping Material

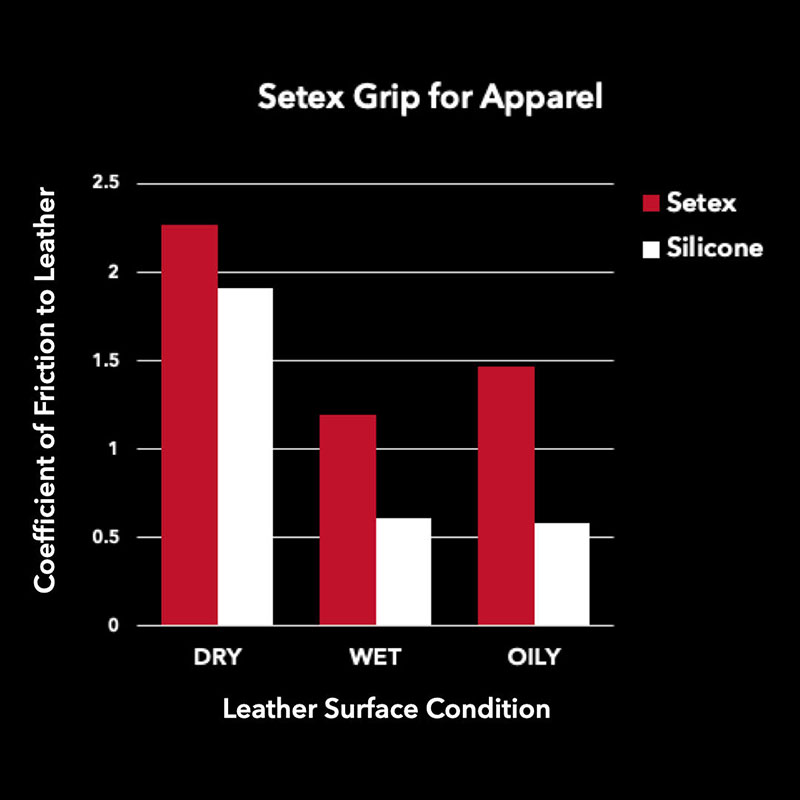

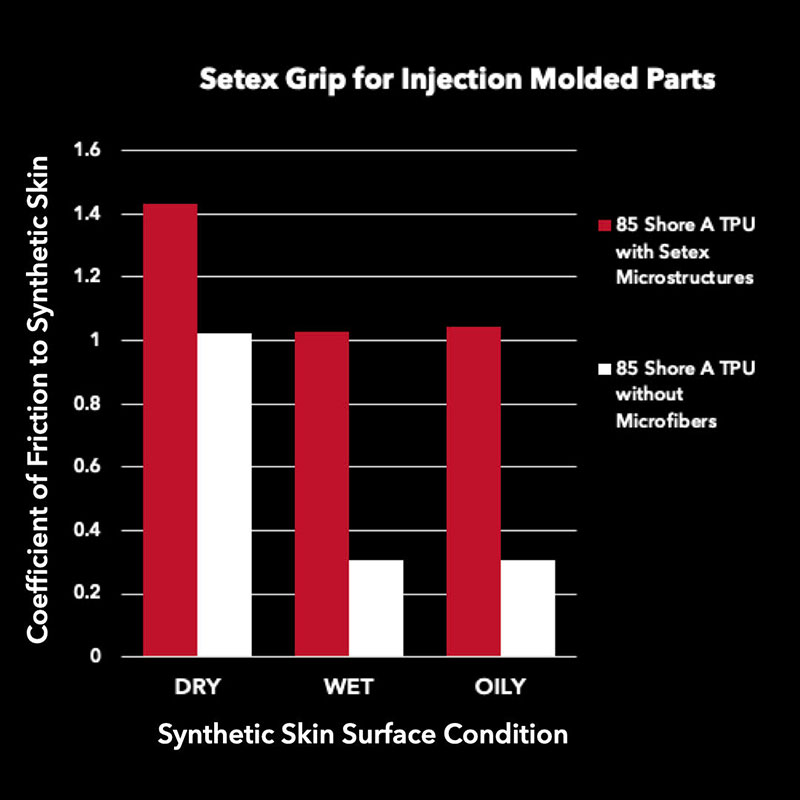

Setex gripping fabric provides up to 350% more grip in slick conditions, especially for items in contact with skin. You can find our geckogrip technology in our market-leading Setex eyewear, earbuds, gaming, and sports products, which are sold across North America, Europe, and Asia. Businesses use our grip material and technology in gripping and handling applications across a broad spectrum of industries including medical, electronics, semiconductor, construction, and home applications.

Attributes and Benefits

Range of Materials Supported: Setex grip material can be formed from a range of castable plastics and elastomers, in film format or bulk parts. We can introduce Setex surfaces to our partners’ products via in-mold tool design.

Customizable Performance: Setex Grip can be designed with varying grip or friction strengths to fit your application’s needs.

Dry/Residue-Free: Setex Grip is completely dry, providing amazing gripping or friction without the stickiness and residue of chemically treated pads.

Comfort: Setex Grip can be tailored to a variety of gripping fabrics and forms, eliminating the abrasive feel of sandpaper pads and other rough materials.

Low Profile/Conformable: Setex Grip can be made film-thin and conform to a wide range of shapes.

The Science

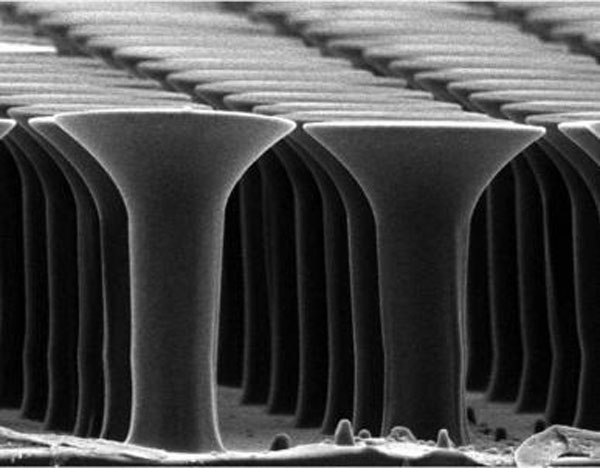

Setex Grip is a high friction microfiber surface inspired by microscopic hairs, or setae, on gecko’s feet that can be incorporated into molded parts and surfaces. The grip material retains around 60%-70% of its friction in wet, oily, or sweaty conditions. Competing materials, such as rubber, can lose 90% of their friction when exposed to such conditions. Setex geckogrip can be incorporated onto a molding tool’s surface, so the resulting molded part is produced with high friction microfibers on the surface, directly integrated and made from the same materials as the part. Setex Grip is also available as a thermoplastic elastomer pad, with or without a conventional pressure-sensitive adhesive backing. It is available in sheet form with a pressure-sensitive adhesive or thermoplastic polyurethane (TPU) backing for incorporation onto textiles for sporting apparel applications. Setex Technologies has demonstrated the ability to mold its high friction Setex Grip microfibers out of a wide range of polymer chemistries and hardnesses including TPU, TPO, Nylons, PC/ABS, TPE, SEBS and silicones.

Setex Grip Microscopic View

Microscopic video showing the Setex microstructures gripping on to synthetic skin as it is pushed sideways.