This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Mounting & Handling

Glass

THE TECH

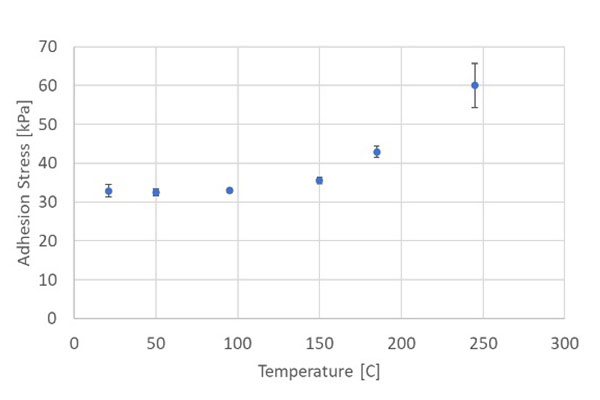

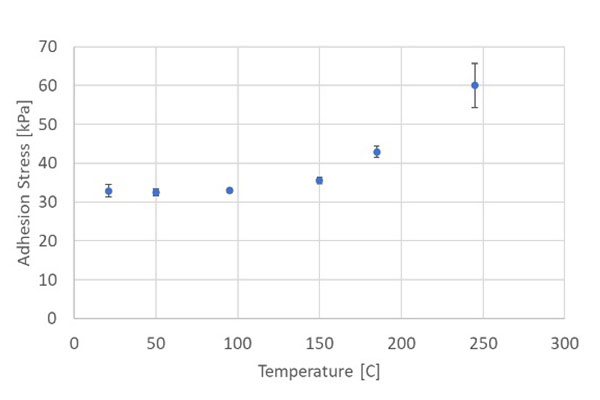

Low and high temperature performance with no degradation are a result of the mechanical nature of Setex’s dry microstructured tape. The properties of the gecko-inspired dry adhesive arise from the microstructure shape and do not rely on any glues or tacky materials that fail at low or high temperatures. Setex tapes have been shown to adhere at temperatures as low as -20C and as high as 300C.

The dry adhesive will bond to smooth, hard, clean surfaces with high shear strength, and can be easily repositioned, cleaned, and reused.

High Temperature Glass

THE TECH

Fragile Components

THE TECH

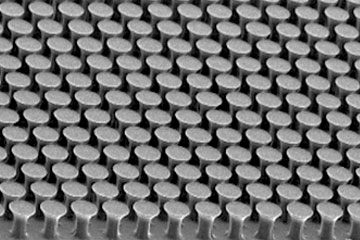

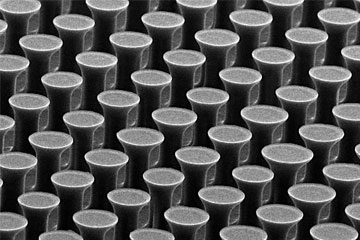

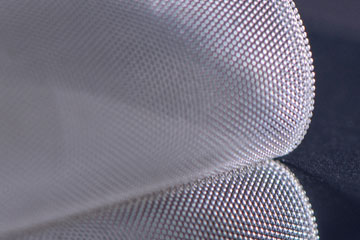

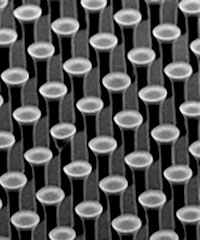

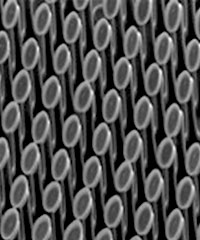

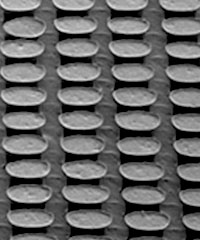

Setex’s gecko-inspired adhesive tape, inspired by the microscopic hairs, or setae, of a gecko’s foot, is tunable in strength, can be reused thousands of times, and is low residue. While the gecko has one evolutionarily-optimized type of toe hair, Setex can make an extensive variety of fiber shapes and dimensions. Small changes in the microgeometry, like the shape of the tip or the height of the fiber, result in different adhesive and frictional properties for Setex tapes and grips, enabling fine-tuning of adhesive properties, even the ability to independently tune shear and peel strength.

The tunability of the dry adhesive makes it ideal for handling fragile components. Setex tape can be finely tuned to the shear and peel strength that the part handling operation requires, enabling the movement of even the most fragile parts without leaving residue for thousands of cycles. The mechanical nature of the adhesive means it also works in a vacuum.

Vertical

Angled

Hierarchical

Eliptical

Nanostructures

Reusable Device Mounting

Mounting adhesives are typically single use and can leave residue that is difficult to remove. Setex dry adhesive technology can be applied to a wide range of applications to mount monitoring devices, sensors, and other technology to smooth, hard surfaces, maintaining the option to reuse or reapply in different locations without leaving behind any sticky residue. The dry adhesive technology can also be used in extreme high and low temperatures.

THE TECH

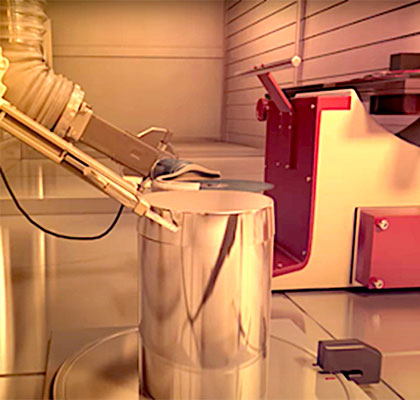

End Effectors

THE TECH

Performance over 1,000 Peel Cycles